"Acetic" redirects here. It is not to be confused with

Ascetic.

| Acetic acid |

|---|

|

|

|

|

|

|

|

|

|

|

|

| Identifiers |

|---|

| Abbreviations | AcOH |

| CAS number | 64-19-7  |

| PubChem | 176 |

| ChemSpider | 171  |

| UNII | Q40Q9N063P  |

| EC number | 200-580-7 |

| UN number | 2789 |

| DrugBank | DB03166 |

| KEGG | D00010  |

| MeSH | Acetic+acid |

| ChEBI | CHEBI:15366  |

| ChEMBL | CHEMBL539  |

| IUPHAR ligand | 1058 |

| RTECS number | AF1225000 |

| ATC code | G01AD02,S02AA10 |

| Beilstein Reference | 506007 |

| Gmelin Reference | 1380 |

| 3DMet | B00009 |

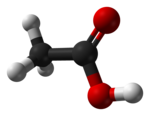

| Jmol-3D images | Image 1 |

|

|

|

|

| Properties |

|---|

| Molecular formula | C2H4O2 |

| Molar mass | 60.05 g mol−1 |

| Appearance | Colourless liquid |

| Odor | vinegar-like |

| Density | 1.049 g cm-3 |

| Melting point | 16 to 17 °C; 61 to 62 °F; 289 to 290 K |

| Boiling point | 118 to 119 °C; 244 to 246 °F; 391 to 392 K |

| Solubility in water | Miscible |

| log P | -0.322 |

| Acidity (pKa) | 4.76 |

| Basicity (pKb) | 9.198 (basicity of acetate ion) |

| Refractive index(nD) | 1.371 |

| Viscosity | 1.22 mPa s |

| Dipole moment | 1.74 D |

| Thermochemistry |

|---|

Specific

heat capacity C | 123.1 J K-1 mol-1 |

Std molar

entropy So298 | 158.0 J K-1 mol-1 |

Std enthalpy of

formation ΔfHo298 | -483.88--483.16 kJ mol-1 |

Std enthalpy of

combustionΔcHo298 | -875.50--874.82 kJ mol-1 |

| Hazards |

|---|

| MSDS | External MSDS |

| GHS pictograms |   |

| GHS signal word | Danger |

| GHS hazard statements | H226, H314 |

| GHS precautionary statements | P280, P305+351+338, P310 |

| EU Index | 607-002-00-6 |

| EU classification |  C C |

| R-phrases | R10, R35 |

| S-phrases | (S1/2), S23, S26, S45 |

| NFPA 704 |

|

| Flash point | 40 °C (104 °F; 313 K) |

| Explosive limits | 4-16% |

| LD50 | 3.31 g kg-1, oral (rat) |

| Related compounds |

|---|

| Related carboxylic acids | Formic acid

Propionic acid |

| Related compounds | Acetaldehyde

|

| Supplementary data page |

|---|

Structure and

properties | n, εr, etc. |

Thermodynamic

data | Phase behaviour

Solid, liquid, gas |

| Spectral data | UV, IR, NMR, MS |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C (77 °F), 100 kPa) |

(verify) (what is: (verify) (what is:  / / ?) ?) |

| Infobox references |

| |

Acetic acid // (systematically named

ethanoic acid //) is an

organic compound with the

chemical formulaCH

3COOH (also written as CH

3CO

2H or C

2H

4O

2). It is a colourless liquid that when undiluted is also called

glacial acetic acid.

Vinegar is roughly 3%-5% acetic acid by volume, making acetic acid the main component of vinegar apart from water. Acetic acid has a distinctive sour taste and pungent smell. Besides its production as household vinegar, it is mainly produced as a precursor to polyvinylacetate and cellulose acetate. Although it is classified as a

weak acid, concentrated acetic acid is corrosive and can attack the skin.

The global demand of acetic acid is around 6.5 million

tonnes per year (Mt/a), of which approximately 1.5 Mt/a is met by recycling; the remainder is manufactured from

petrochemical feedstock.

[10] As a chemical reagent, biological sources of acetic acid are of interest but generally uncompetitive. Vinegar is dilute acetic acid, often produced by

fermentation and subsequent oxidation of

ethanol.

Nomenclature[edit]

The

trivial name acetic acid is the most commonly used and

preferred IUPAC name. The systematic name

ethanoic acid, a valid

IUPAC name, is constructed according to the substitutive nomenclature.

[3] The name

acetic acid derives from

acetum, the

Latin word for

vinegar, and is related to the word

acid itself.

Glacial acetic acid is a name for water-free (

anhydrous) acetic acid. Similar to the

German name

Eisessig (

ice-vinegar), the name comes from the ice-like crystals that form slightly below room temperature at 16.6 °C (61.9 °F) (the presence of 0.1% water lowers its melting point by 0.2 °C).

[11]

A common abbreviation for acetic acid is

AcOH, where

Ac stands for the

acetyl group CH

3−C(=O)−.

Acetate (CH

3COO

–) is abbreviated

AcO–. The

Ac is not to be confused with the abbreviation for the

chemical element actinium.

[12] To better reflect its structure, acetic acid is often written as CH

3–C(O)OH, CH

3–C(=O)OH, CH

3COOH, and CH

3CO

2H. In the context of

acid-base reactions, the abbreviation

HAc is sometimes used,

[13] where

Ac instead stands for acetate. Acetate is the

ion resulting from loss of

H+ from acetic acid. The name

acetate can also refer to a

salt containing this anion, or an

ester of acetic acid.

[14]

History[edit]

Vinegar was known early in civilization as the natural result of exposure of

beer and

wine to air, because acetic acid-producing bacteria are present globally. The use of acetic acid in

alchemy extends into the 3rd century BC, when the

Greek philosopher

Theophrastus described how vinegar acted on metals to produce

pigments useful in art, including

white lead (

lead carbonate) and

verdigris, a green mixture of

copper salts including

copper(II) acetate. Ancient

Romans boiled soured wine to produce a highly sweet syrup called

sapa.

Sapa that was produced in lead pots was rich in

lead acetate, a sweet substance also called

sugar of lead or

sugar of Saturn, which contributed to

lead poisoning among the Roman aristocracy.

[15]

In the

Renaissance, glacial acetic acid was prepared through the

dry distillation of certain metal acetates (the most noticeable one being copper(II) acetate). The 16th-century

German alchemist

Andreas Libavius described such a procedure, and he compared the glacial acetic acid produced by this means to vinegar. The presence of water in vinegar has such a profound effect on acetic acid's properties that for centuries chemists believed that glacial acetic acid and the acid found in vinegar were two different substances. French chemist

Pierre Adet proved them identical.

[15][16]

Crystallised acetic acid.

By 1910, most glacial acetic acid was obtained from the "pyroligneous liquor" from distillation of wood. The acetic acid was isolated from this by treatment with

milk of lime, and the resulting

calcium acetate was then acidified with

sulfuric acid to recover acetic acid. At that time, Germany was producing 10,000

tons of glacial acetic acid, around 30% of which was used for the manufacture of

indigo dye.

[15][18]

Because both

methanol and

carbon monoxide are commodity raw materials, methanol carbonylation long appeared to be attractive precursors to acetic acid.

Henri Dreyfus at

British Celanese developed a methanol carbonylation pilot plant as early as 1925.

[19] However, a lack of practical materials that could contain the corrosive reaction mixture at the high

pressures needed (200

atm or more) discouraged commercialization of these routes. The first commercial methanol carbonylation process, which used a

cobalt catalyst, was developed by German chemical company

BASF in 1963. In 1968, a

rhodium-based catalyst (

cis−[Rh(CO)

2I

2]

−) was discovered that could operate efficiently at lower pressure with almost no by-products. US chemical company

Monsanto Company built the first plant using this catalyst in 1970, and rhodium-catalyzed methanol carbonylation became the dominant method of acetic acid production (see

Monsanto process). In the late 1990s, the chemicals company

BP Chemicals commercialized the

Cativa catalyst ([Ir(CO)

2I

2]

−), which is promoted by

ruthenium for greater efficiency. This

iridium-catalyzed

Cativa process is

greener and more efficient

[20] and has largely supplanted the Monsanto process, often in the same production plants.

In the interstellar medium[edit]

Acetic acid was discovered in the

interstellar medium in 1996 by a team led by David Mehringer

[21] who detected it using the former Berkeley-Illinois-Maryland Association array at the

Hat Creek Radio Observatory and the former Millimeter Array located at the

Owens Valley Radio Observatory. It was first detected in the

Sagittarius B2 North molecular cloud (also known as the Sgr B2 Large Molecule Heimat source). Acetic acid has the distinction of being the first molecule discovered in the interstellar medium using solely

radio interferometers; in all previous ISM molecular discoveries made in the millimeter and centimeter wavelength regimes, single dish radio telescopes were at least partly responsible for the detections.

[21]

Chemical properties[edit]

Acidity[edit]

The hydrogen center in the

carboxyl group (−COOH) in carboxylic acids such as acetic acid can separate from the molecule by ionization:

- CH3CO2H → CH3CO2- + H+

Because of this release of the

proton (H

+), acetic acid has acidic character. Acetic acid is a weak

monoprotic acid. In aqueous solution, it has a

pKa value of 4.76.

[22] Its

conjugate base is

acetate (CH

3COO

−). A 1.0

M solution (about the concentration of domestic vinegar) has a

pH of 2.4, indicating that merely 0.4% of the acetic acid molecules are dissociated.

[23]

Cyclic dimer of acetic acid; dashed

green lines represent hydrogen bonds

Structure[edit]

In solid acetic acid, the molecules form pairs (

dimers), being connected by

hydrogen bonds.

[24] The dimers can also be detected in the vapour at 120 °C (248 °F). Dimers also occur in the liquid phase in dilute solutions in non-hydrogen-bonding solvents, and a certain extent in pure acetic acid,

[25] but are disrupted by hydrogen-bonding solvents. The dissociation

enthalpy of the dimer is estimated at 65.0–66.0 kJ/mol, and the dissociation entropy at 154–157 J mol

−1 K

−1.

[26] Other lower carboxylic acids dimerize in a similar fashion.

[27]

Solvent properties[edit]

Chemical reactions[edit]

Organic chemistry[edit]

- CH3COOH → CH4 + CO2

- CH3COOH → CH2CO + H2O

Reactions with inorganic compounds[edit]

- Mg + 2 CH3COOH → (CH3COO)2Mg + H2

Because

aluminium forms a

passivating acid-resistant film of

aluminium oxide, aluminium tanks are used to transport acetic acid. Metal acetates can also be prepared from acetic acid and an appropriate

base, as in the popular "

baking soda + vinegar" reaction:

- NaHCO3 + CH3COOH → CH3COONa + CO2 + H2O

Biochemistry[edit]

At physiological pHs, acetic acid is usually fully ionized to

acetate. The

acetyl group, derived from acetic acid, is fundamental to all forms of life. When bound to

coenzyme A, it is central to the

metabolism of

carbohydrates and

fats. Unlike longer-chain carboxylic acids (the

fatty acids), acetic acid does not occur in natural

triglycerides. However, the artificial triglyceride

triacetin (glycerine triacetate) is a common food additive and is found in cosmetics and topical medicines.

[35]

Production[edit]

Purification and concentration plant for acetic acid in 1884

Acetic acid is produced industrially both synthetically and by bacterial

fermentation. About 75% of acetic acid made for use in the chemical industry is made by the

carbonylation of methanol, explained below.

[10] Alternative methods account for the rest. The biological route accounts for only about 10% of world production, but it remains important for the production of vinegar, as many food purity laws stipulate that vinegar used in foods must be of biological origin. As of 2003–2005, total worldwide production of virgin acetic acid was estimated at 5 Mt/a (million tonnes per year), approximately half of which was then produced in the

United States.

European production stood at approximately 1 Mt/a and was declining, and 0.7 Mt/a were produced in

Japan. Another 1.5 Mt were recycled each year, bringing the total world market to 6.5 Mt/a.

[37][38] Since then the global production has increased to 10.7 Mt/a (in 2010), and further, however, slowing increase in production is predicted.

[39] The two biggest producers of virgin acetic acid are

Celanese and

BP Chemicals. Other major producers include

Millennium Chemicals,

Sterling Chemicals,

Samsung,

Eastman, and

Svensk Etanolkemi.

[40]

Methanol carbonylation[edit]

Most acetic acid is produced by methanol

carbonylation. In this process, methanol and

carbon monoxide react to produce acetic acid according to the equation:

- CH3OH + CO → CH3COOH

- CH3OH + HI → CH3I + H2O

- CH3I + CO → CH3COI

- CH3COI + H2O → CH3COOH + HI

Two related processes for the carbonylation of methanol: the rhodium-catalyzed

Monsanto process, and the iridium-catalyzed

Cativa process. The latter process is

greener and more efficient

[20] and has largely supplanted the former process, often in the same production plants. Catalytic amounts of water are used in both processes, but the Cativa process requires less, so the

water-gas shift reaction is suppressed, and fewer byproducts are formed.

By altering the process conditions,

acetic anhydride may also be produced on the same plant using the rhodium catalysts.

[42]

Acetaldehyde oxidation[edit]

Prior to the commercialization of the Monsanto process, most acetic acid was produced by oxidation of

acetaldehyde. This remains the second-most-important manufacturing method, although it is usually uncompetitive with the carbonylation of methanol.

- 2 C4H10 + 5 O2 → 4 CH3COOH + 2 H2O

The typical reaction is conducted at

temperatures and pressures designed to be as hot as possible while still keeping the butane a liquid. Typical reaction conditions are 150 °C (302 °F) and 55 atm.

[43] Side-products may also form, including

butanone,

ethyl acetate,

formic acid, and

propionic acid. These side-products are also commercially valuable, and the reaction conditions may be altered to produce more of them where needed. However, the separation of acetic acid from these by-products adds to the cost of the process.

[44]- 2 CH3CHO + O2 → 2 CH3COOH

Ethylene oxidation[edit]

Acetaldehyde may be prepared from

ethylene via the

Wacker process, and then oxidized as above. In more recent times, chemical company

Showa Denko, which opened an ethylene oxidation plant in

Ōita,

Japan, in 1997, commercialized a cheaper single-stage conversion of ethylene to acetic acid.

[45] The process is catalyzed by a

palladium metal catalyst supported on a

heteropoly acid such as

tungstosilicic acid. It is thought to be competitive with methanol carbonylation for smaller plants (100–250 kt/a), depending on the local price of ethylene. The approach will be based on utilizing a novel selective photocatalytic oxidation technology for the selective oxidation of ethylene and ethane to acetic acid. Unlike traditional oxidation catalysts, the selective oxidation process will use UV light to produce acetic acid at ambient temperatures and pressure.

Oxidative fermentation[edit]

For most of human history, acetic acid bacteria of the genus

Acetobacter have made acetic acid, in the form of vinegar. Given sufficient oxygen, these bacteria can produce vinegar from a variety of alcoholic foodstuffs. Commonly used feeds include

apple cider,

wine, and fermented

grain,

malt,

rice, or

potato mashes. The overall chemical reaction facilitated by these bacteria is:

- C2H5OH + O2 → CH3COOH + H2O

A dilute alcohol solution inoculated with

Acetobacter and kept in a warm, airy place will become vinegar over the course of a few months. Industrial vinegar-making methods accelerate this process by improving the supply of

oxygen to the bacteria.

[46]

The first batches of vinegar produced by fermentation probably followed errors in the

winemaking process. If

must is fermented at too high a temperature, acetobacter will overwhelm the

yeast naturally occurring on the

grapes. As the demand for vinegar for culinary, medical, and sanitary purposes increased, vintners quickly learned to use other organic materials to produce vinegar in the hot summer months before the grapes were ripe and ready for processing into wine. This method was slow, however, and not always successful, as the vintners did not understand the process.

[47]

One of the first modern commercial processes was the "fast method" or "German method", first practised in Germany in 1823. In this process, fermentation takes place in a tower packed with wood shavings or

charcoal. The alcohol-containing feed is trickled into the top of the tower, and fresh

air supplied from the bottom by either natural or forced

convection. The improved air supply in this process cut the time to prepare vinegar from months to weeks.

[48]

Nowadays, most vinegar is made in submerged tank

culture, first described in 1949 by Otto Hromatka and Heinrich Ebner.

[49] In this method, alcohol is fermented to vinegar in a continuously stirred tank, and oxygen is supplied by bubbling air through the solution. Using modern applications of this method, vinegar of 15% acetic acid can be prepared in only 24 hours in batch process, even 20% in 60-hour fed-batch process.

[47]

When there is over-oxidation, acetic acid will convert to CO

2 and H

2O, this will decrease acetic acid production. Acetic acid concentrations above 6% of the total culture and avoiding the total depletion of ethanol will prevent overoxidization.

[citation needed]

Anaerobic fermentation[edit]

Species of

anaerobic bacteria, including members of the genus

Clostridium or

Acetobacterium can convert sugars to acetic acid directly, without using ethanol as an intermediate. The overall chemical reaction conducted by these bacteria may be represented as:

- C6H12O6 → 3 CH3COOH

- 2 CO2 + 4 H2 → CH3COOH + 2 H2O

This ability of

Clostridium to utilize sugars directly, or to produce acetic acid from less costly inputs, means that these bacteria could potentially produce acetic acid more efficiently than ethanol-oxidizers like

Acetobacter. However,

Clostridium bacteria are less acid-tolerant than

Acetobacter. Even the most acid-tolerant

Clostridium strains can produce vinegar of only a few per cent acetic acid, compared to

Acetobacter strains that can produce vinegar of up to 20% acetic acid. At present, it remains more cost-effective to produce vinegar using

Acetobacter than to produce it using

Clostridium and then concentrate it. As a result, although acetogenic bacteria have been known since 1940, their industrial use remains confined to a few niche applications.

[50]

Acetic acid is a chemical

reagent for the production of chemical compounds. The largest single use of acetic acid is in the production of vinyl acetate

monomer, closely followed by acetic anhydride and ester production. The volume of acetic acid used in vinegar is comparatively small.

[10][38]

Vinyl acetate monomer[edit]

- 2 H3C–COOH + 2 C2H4 + O2 → 2 H3C–CO–O–CH=CH2 + 2 H2O

Ester production[edit]

- H3C-COOH + HO-R → H3C-CO-O-R + H2O, (R = a general alkyl group)

Most acetate esters, however, are produced from

acetaldehyde using the

Tishchenko reaction. In addition, ether acetates are used as solvents for

nitrocellulose,

acrylic lacquers,

varnish removers, and wood stains. First, glycol monoethers are produced from

ethylene oxide or

propylene oxide with alcohol, which are then esterified with acetic acid. The three major products are ethylene glycol monoethyl ether acetate (EEA), ethylene glycol monobutyl ether acetate (EBA), and propylene glycol monomethyl ether acetate (PMA, more commonly known as PGMEA in semiconductor manufacturing processes, where it is used as a resist solvent). This application consumes about 15% to 20% of worldwide acetic acid. Ether acetates, for example EEA, have been shown to be harmful to human reproduction.

[38]

Acetic anhydride[edit]

The product of the

condensation of two molecules of acetic acid is

acetic anhydride. The worldwide production of acetic anhydride is a major application, and uses approximately 25% to 30% of the global production of acetic acid. The main process involves dehydration of acetic acid to give

ketene at 700-750 °C. Ketene is thereafter reacted with acetic acid to obtain the anhydride:

[52]- CH3CO2H → CH2=C=O + H2O

- CH3CO2H + CH2=C=O → (CH3CO)2O

Use as solvent[edit]

Glacial acetic acid is used in analytical chemistry for the estimation of weakly alkaline substances such as organic amides. Glacial acetic acid is a much weaker

base than water, so the amide behaves as a strong base in this medium. It then can be titrated using a solution in glacial acetic acid of a very strong acid, such as

perchloric acid.

[54]

Medical use[edit]

Vinegar[edit]

Vinegar is typically 4-18% acetic acid by mass. Vinegar is used directly as a

condiment, and in the

pickling of vegetables and other foods. Table vinegar tends to be more diluted (4% to 8% acetic acid), while commercial food pickling employs solutions that are more concentrated. The amount of acetic acid used as vinegar on a worldwide scale is not large, but is by far the oldest and best-known application.

[56]

Other derivatives[edit]

Organic or inorganic salts are produced from acetic acid, including:

Substituted acetic acids produced include:

Amounts of acetic acid used in these other applications together (apart from TPA) account for another 5–10% of acetic acid use worldwide. These applications are, however, not expected to grow as much as TPA production.

[38]

Health effects and safety[edit]

Concentrated acetic acid is

corrosive to skin and must, therefore, be handled with appropriate care, since it can cause skin burns, permanent eye damage, and irritation to the mucous membranes.

[57][58] These burns or blisters may not appear until hours after exposure.

Latex gloves offer no protection, so specially resistant gloves, such as those made of

nitrile rubber, are worn when handling the compound. Concentrated acetic acid can be ignited with difficulty in the laboratory. It becomes a flammable risk if the ambient temperature exceeds 39 °C (102 °F), and can form explosive mixtures with air above this temperature (

explosive limits: 5.4–16%). Acetic acid is a strong eye, skin, and mucous membrane irritant. Prolonged skin contact with glacial acetic acid may result in tissue destruction. Inhalation exposure (8 hours) to acetic acid vapours at 10 ppm could produce some irritation of eyes, nose, and throat; at 100 ppm marked lung irritation and possible damage to lungs, eyes, and skin might result. Vapour concentrations of 1,000 ppm cause marked irritation of eyes, nose and upper respiratory tract and cannot be tolerated. These predictions were based on animal experiments and industrial exposure. Skin sensitization to acetic acid is rare, but has occurred. It has been reported that, 12 workers exposed for two or more years to an estimated mean acetic acid airborne concentration of 51 ppm, there were symptoms of conjunctive irritation, upper respiratory tract irritation, and hyperkeratotic dermatitis. Exposure to 50 ppm or more is intolerable to most persons and results in intensive lacrimation and irritation of the eyes, nose, and throat, with pharyngeal oedema and chronic bronchitis. Un acclimatized humans experience extreme eye and nasal irritation at concentrations in excess of 25 ppm, and conjunctivitis from concentrations below 10 ppm has been reported. In a study of 5 workers exposed for 7 to 12 years to concentrations of 80 to 200 ppm at peaks, the principal findings were blackening and hyperkeratosis of the skin of the hands, conjunctivitis (but no corneal damage), bronchitis and pharyngitis, and erosion of the exposed teeth (incisors and canines).

[59]

The hazards of solutions of acetic acid depend on the concentration. The following table lists the

EU classification of acetic acid solutions:

[60]

Concentration

by weight | Molarity | Classification | R-Phrases |

|---|

| 10–25% | 1.67–4.16 mol/L | Irritant (Xi) | R36/38 |

| 25–90% | 4.16–14.99 mol/L | Corrosive (C) | R34 |

| >90% | >14.99 mol/L | Corrosive (C) Flammable (F) | R10, R35 |

Solutions at more than 25% acetic acid are handled in a fume hood because of the pungent, corrosive vapor.

Dilute acetic acid, in the form of

vinegar, is practically harmless. However, ingestion of stronger solutions is dangerous to human and animal life. It can cause severe damage to the

digestive system, and a potentially lethal change in the acidity of the

blood.

See also[edit]